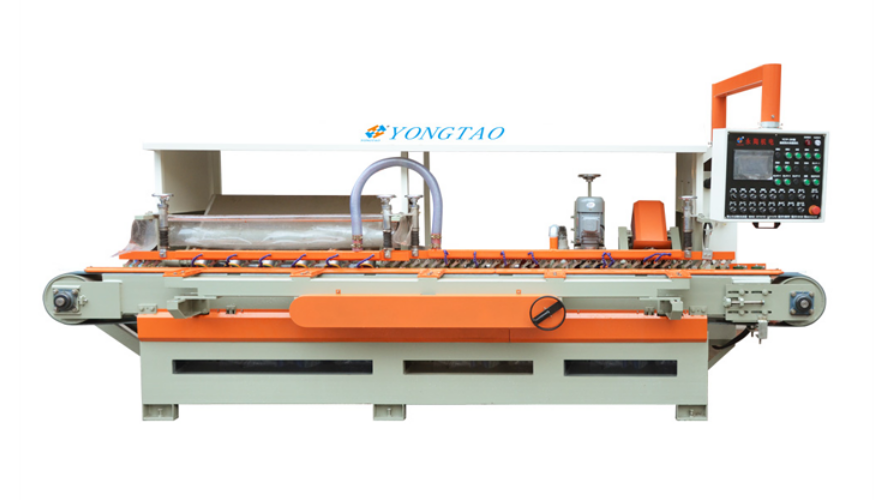

Function of YCYP-200 Quartz Countertop Backsplash Bullnose Bevel Edge Polishing Machine

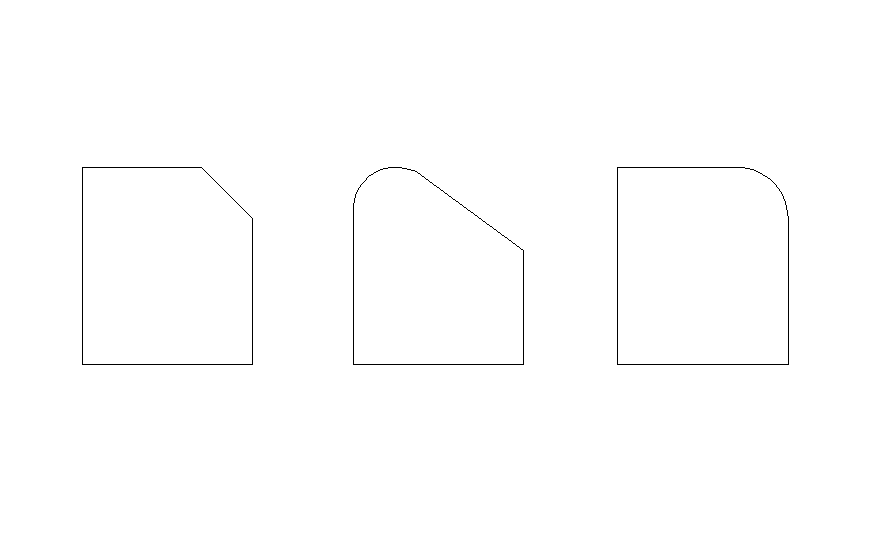

YCYP-200 Quartz Countertop Backsplash Bullnose Bevel Edge Polishing Machine, this quartz processing machine is mainly used for processing the edge of the back splash of quartz kitchen tops, such as small round and side edge polishing. It can make R3 round edge, bevel edge, as well as front strips arc and 23 degrees bevel edges. high smoothness, high processing efficiency, conveyor belt transmission, large output, save a lot of labor, suitable for professional processing quartz stone Backs plash.kitchen tops. It can be used as quartz bullnose edge polisher and countertop backsplash polisher.

Put a material on the belt of machine, the strips will go through the first chamfer motor, the Angle of chamfer can be adjusted according to their own needs. The second motor is a fixed round shaped grinding wheel, and you can install the grinding tool of the desired arc size and shape according to your own needs. The third part are 4 pcs of bevel edge polishing head, which can be adjust the polishing angles to match the first chamfer head. The last part are 6 pcs of bullnose polishing head, it can polish R3 round edge, usually using together with the second grinding wheel. It adopts swing structure to deal the bullnose.

Characteristic of YCYP-200 Quartz Countertop Backsplash Bullnose Bevel Edge Polishing Machine

1. The stopped baffle adjusted by handle wheels, it can be designed by motor adjusting.

2. The press wheel use PET materials, which has a good elasticity, can make a good press to the strips

3. Use hollow square pipe and small water pipe to cool the wheels.

4. A good water-proof to ensure the motor working in a good condition

5. Using the grinding slice to polish, the slice and polish pad can be easy replaced

Parameter of YCYP-200 Quartz Countertop Backsplash Bullnose Bevel Edge Polishing Machine

No. | Name | Parameter |

1 | Motor power of chamfer | 3kw |

2 | Chamfer angles (adjustable) | Down 30°, up 45° |

3 | Diameter of grinding wheel | Ø180*60mm |

4 | Bevel polishing angle | Adjustable |

5 | Numbers of R3 round polishing head | 6pcs |

6 | Diameter of grinding slice | Ø125mm |

7 | Diameter of chamfer wheel | Ø200*60mm |

8 | Motor power of grinding wheel | 3kw |

9 | Motor power of bevel polishing head | 0.75kw*4 |

10 | Motor power of R3 round polishing head | 1.5kw*3 |

11 | Motor power of swing | 3kw |

12 | Conveyor belt width | 200mm |

13 | Processing width | 40-150mm |

14 | Processing thickness | 10-30mm |

15 | Processing speed | 1-5m/min |

16 | Size of machine | 4.5*1.5*1.8m |

17 | Total power | 18.7kw |

18 | Weight | 3T |

0086-18665475362

0086-18665475362  [email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China