In the realm of advanced cutting technology, the YJ-3020-5L AC 5 Axis Water Jet Marble Cutting Machine emerges as a game-changer. Originating from Foshan, Guangdong, China, and brought to you by Yongtao, a renowned brand among waterjet manufacturers.

This remarkable water jet marble cutter is designed to handle a wide range of materials including porcelain large format tiles, rock slab, ceramic board, quartz stone, marble, stone, granite, and artificial stone. It offers exceptional cutting capabilities with a cutting angle that can be adjusted from 0 to 55 degrees, making it ideal for creating products like washbasins, rock slab tables, tea tables, reception desks, and wardrobes. The surface of the cut is free from cracks, ensuring a flawless cutting effect and perfect stitching.

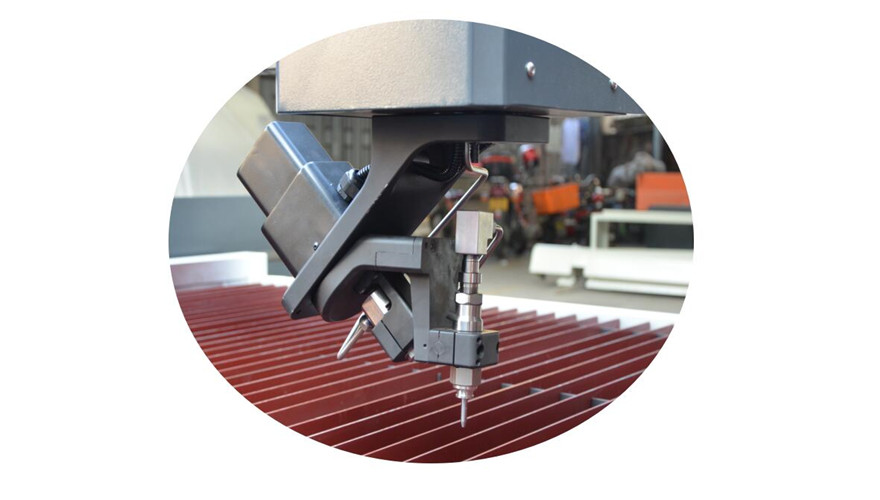

The YJ-3020-5L AC 5 Axis Water Jet Marble Cutting Machine stands out with its unique features. With an AC 5-axis design that realizes the linkage of X, Y, Z, A, and C, it provides high precision cutting. Equipped with high-quality servo motors and servo drivers, it controls cutting accuracy precisely. It can perform 0-55 degree cutting, enabling large-angle cuts on various materials. Corner cutting achieves a linear cutting effect without dead angles or edge collapse.

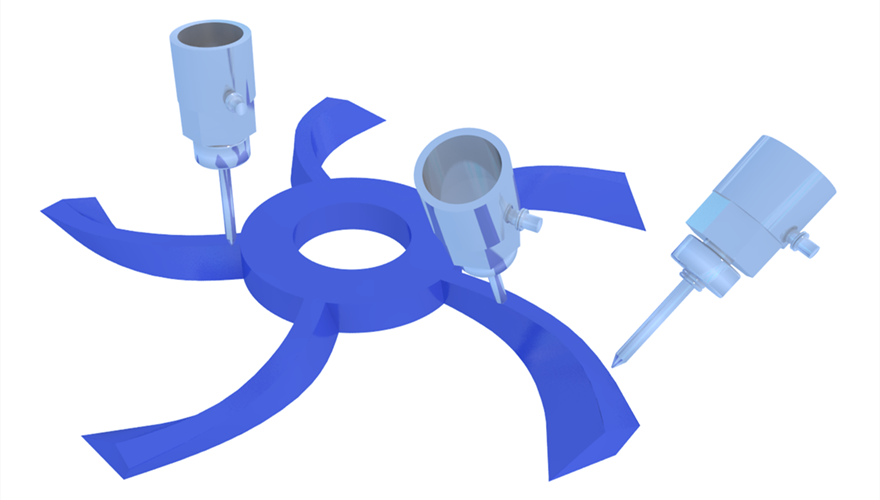

A set of this water jet cutting configuration includes major components such as a water jet cutting table for sale, a CNC water jet control system, an abrasive supply system, a water jet ultra-high pressure supercharging system, and a circulating cooling system.

In terms of machine parameters, it has a maximum cutting thickness of 40mm for metal and 50mm for rock slab, ceramic slab, stone, glass, marble, quartz stone, granite, and artificial stone. The maximum cutting size is 3000mm by 2000mm, with a machining accuracy of ±0.1mm.

If you're in search of the best water jet machine, look no further than the YJ-3020-5L AC 5 Axis Water Jet Marble Cutting Machine. As one of the leading 5 axis waterjet for sale and cnc water jet cutter for sale, this 5 axis waterjet cutting machine is a must-have for those seeking top-notch cutting solutions. Its main parts are processed by imported precision CNC machine tools, guaranteeing accuracy and ensuring that your processed products always stay at the industry's leading level.

Packaging size:

3020 AC five-axis water jet cutting table package size: 4.1m*3.2m*1.65m

Package size of water jet supercharging system: 1.3m*0.95m*1.25m

Package size of water jet abrasive feeding system: 0.6m*0.6m*0.95m

Package size of CNC water jet control system: 0.65m*0.65m*1.67m

Technical parameters:

Model | YJ-3020-5L AC | |

Structure | Bridge | |

Cutting table size | 3100x2100mm | |

Stroke | X-axis | 3000mm |

Y-axis | 2000mm | |

Z-axis | 130mm | |

CNC Controller | AC Servo System | |

Accuracy | Cutting | ±0.1mm |

Repeat ability | ±0.05mm | |

Traverse speed | 6000/15000 mm/min | |

Power source | 380VAC, 50Hz, 3Phase | |

0086-18665475362

0086-18665475362  [email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China