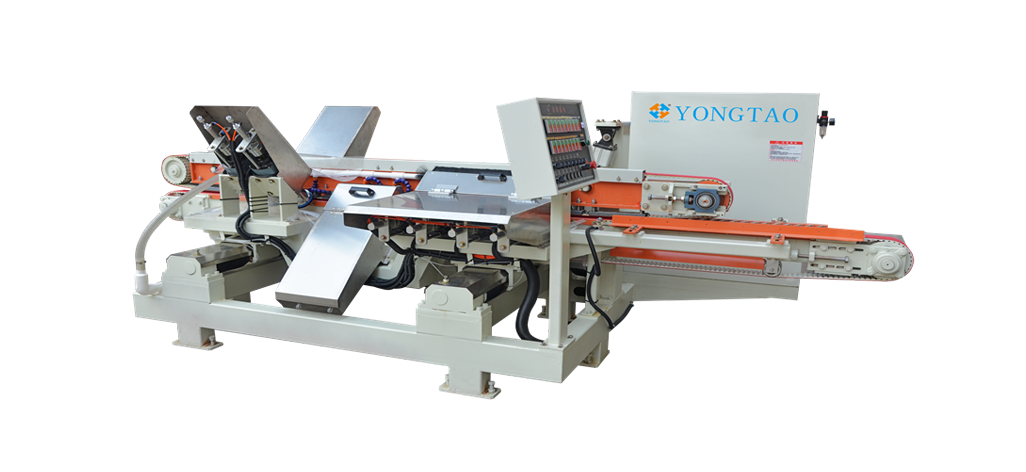

As the stone processing industry continues to demand higher precision, efficiency, and diverse processing capabilities, traditional marble cutting machines and conventional equipment can no longer meet the complex requirements for processing modern quartz, marble, and granite countertops. The 4-axis CNC stone cutting machine developed and manufactured by Yongtao Machinery, with its advanced control system, multi-axis linkage structure, and integrated design, has become the ideal equipment in the field of advanced stone countertop processing. It is widely used in high-end applications such as kitchen and bathroom countertops, engineered slabs, and architectural materials.

2025-04-21

Equipped with a high-performance four-axis CNC system, the machine achieves coordinated control of the X, Y, Z, and C axes, as well as a rotating axis. It is capable of performing precise straight cuts, angled cuts (45°), under-mount sink cutouts, and complex geometric shapes on various types of stone. The equipment supports customizable processing paths and can accurately execute tasks such as circular, oval, diamond, and L-shaped countertop openings, under-mount sink contours, drilling, and four-side beveling. It is particularly suited for complex quartz countertop operations like hole cutting and edge shaping, significantly improving both production efficiency and finished product precision.

In terms of core configuration, Yongtao Machinery adopts a high-rigidity machine bed and a hydraulic drive system, enhancing overall stability and cutting accuracy. The cutting section is equipped with a high-efficiency infrared tool alignment system that can intelligently identify and execute cutting based on different processing requirements, greatly improving workflow efficiency. Notably, the machine is integrated with a high-precision milling head specifically for hole drilling, enabling smooth and high-speed drilling on high-hardness materials like quartz and marble—ideal for rapid cutouts for under-mount sinks, faucet holes, and more. This makes it a true example of intelligent stone machinery.

The software system of this machine also performs exceptionally well, fully supporting CAD file import for seamless integration with design files. Operators can directly load CAD drawings via the touch screen to generate cutting paths, eliminating the need for complex manual programming and reducing operational errors and graphical deviations. This allows for true "what you see is what you get" processing. In addition, the machine features cutting path simulation and an anomaly warning system to further ensure processing safety and stability.

As a high-end marble bridge saw, the Yongtao 4-axis CNC equipment integrates the strengths of traditional stone bridge saws and modern automation. Its robust bridge structure provides wide-span working capability, and its intelligent control panel mirrors the design of a stone bridge cutting machine. It truly embodies high-efficiency, intelligent, and multi-functional design concepts, offering a complete one-stop solution for stone processing enterprises. While enhancing cutting speed and precision, it also greatly reduces labor dependency and processing costs—making it the ideal choice for mass, standardized, and customized quartz countertop production.

2025-04-21 15:54:46

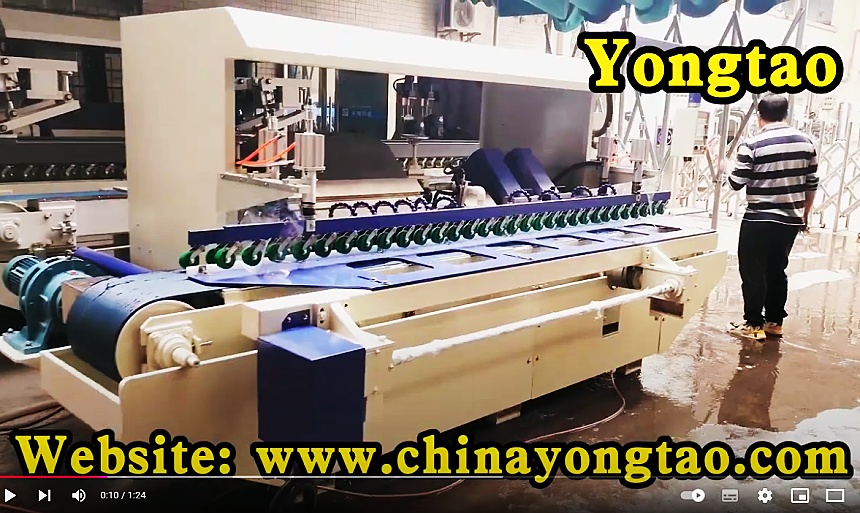

YSXP-800 10 Head Stone profiling machine

11 04,2019

YSXP-800 10 Head Stone profiling machine

VIEW

YSXP-800 10 Head Stone profiling machine

11 04,2019

YSXP-800 10 Head Stone profiling machine

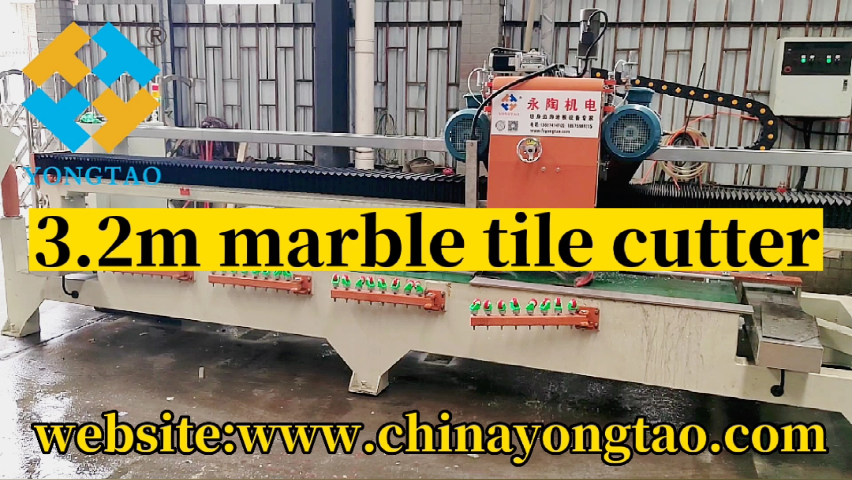

VIEW 3.2m marble tile cutter machine

05 07,2022

Yongtao wet double saw blade marble tile cutter machine, maximum cutting 3200mm, the first blade trimming edge, the second blade cut off. The first head using resin wheel to trim edge, the second head using diamond saw blade. The machine will measure heig

VIEW

3.2m marble tile cutter machine

05 07,2022

Yongtao wet double saw blade marble tile cutter machine, maximum cutting 3200mm, the first blade trimming edge, the second blade cut off. The first head using resin wheel to trim edge, the second head using diamond saw blade. The machine will measure heig

VIEW 6-Head Ceramic Tile Chamfering Machine

10 11,2024

Yongtao Machinery has developed this ceramic tile chamfering machine based on the specific needs of its customers. The machine is equipped with one rough grinding head, two 45-degree chamfering heads,...

VIEW

6-Head Ceramic Tile Chamfering Machine

10 11,2024

Yongtao Machinery has developed this ceramic tile chamfering machine based on the specific needs of its customers. The machine is equipped with one rough grinding head, two 45-degree chamfering heads,...

VIEW YSXP-150 6 Head Automatic Marble Molding Machine

04 15,2019

YSXP-150 6 Head Automatic Marble Molding Machine, this machine is the new generation product of YONGTAO Machinery. It has 2 heads to profile, and 4 heads to polish. The polishing wheel adopts an automatic control system. The machine adopts

VIEW

YSXP-150 6 Head Automatic Marble Molding Machine

04 15,2019

YSXP-150 6 Head Automatic Marble Molding Machine, this machine is the new generation product of YONGTAO Machinery. It has 2 heads to profile, and 4 heads to polish. The polishing wheel adopts an automatic control system. The machine adopts

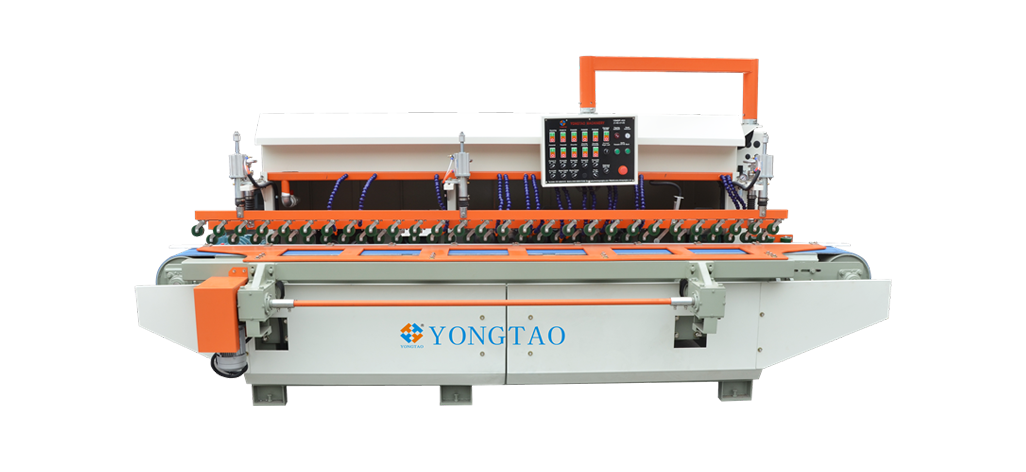

VIEW YSMD 5+3+3 Multifunction Marble Edge Profile Chamfer Polishing Machine

04 15,2019

YSMD 5+3+3 Multifunction Marble Edge Profile Chamfer Polishing Machine,This machine is the new generation product of Yongtao Machinery. It can process single thick slab and double thick slab for all kinds of edge shapes, such as 180 degree round edge, fla

VIEW

YSMD 5+3+3 Multifunction Marble Edge Profile Chamfer Polishing Machine

04 15,2019

YSMD 5+3+3 Multifunction Marble Edge Profile Chamfer Polishing Machine,This machine is the new generation product of Yongtao Machinery. It can process single thick slab and double thick slab for all kinds of edge shapes, such as 180 degree round edge, fla

VIEW YCYP-2500 Quartz Countertop Edge Polishing Machine

05 14,2019

YCYP-2500 Quartz Countertop Edge Polishing Machine,The machine is mainly used to process the quartz countertop edges. It can do R3 round edge, calibrating, grooving, flat polishing. The machine have special pressure structure, each press roller drive bu i

VIEW

YCYP-2500 Quartz Countertop Edge Polishing Machine

05 14,2019

YCYP-2500 Quartz Countertop Edge Polishing Machine,The machine is mainly used to process the quartz countertop edges. It can do R3 round edge, calibrating, grooving, flat polishing. The machine have special pressure structure, each press roller drive bu i

VIEW YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine

04 15,2019

YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine,This machine is one of the latest models of YONGTAO Machinery.The machine is mainly used to process all kinds of single or double thick slab for flat edge, bevel edge, chamfer. It rely on th

VIEW

YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine

04 15,2019

YSMD 11 Head Automatic Granite Flat Bevel Edge Polishing Machine,This machine is one of the latest models of YONGTAO Machinery.The machine is mainly used to process all kinds of single or double thick slab for flat edge, bevel edge, chamfer. It rely on th

VIEW YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine

10 24,2019

YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine,this machine is applied to process the flat edge and bevel edge for the marble, granite stone slabs. Put the slab on the conveyor belt, the conveyor will drive the material into working area. There

VIEW

YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine

10 24,2019

YSMDP-800 1+6-1+2 Stone Flat Bevel Edge Polishing Machine,this machine is applied to process the flat edge and bevel edge for the marble, granite stone slabs. Put the slab on the conveyor belt, the conveyor will drive the material into working area. There

VIEW YSMDP-250 4+2+2 Quartz Double Flat Bevel Edge Polishing Machine

10 08,2019

YSMDP-250 4+2+2 Quartz Double Flat Bevel Edge Polishing Machine,put the material on the conveyor belt, the bottom belt will transport the material into the working area, and the top belt will press the material. At the front of machine, there are 4 st

VIEW

YSMDP-250 4+2+2 Quartz Double Flat Bevel Edge Polishing Machine

10 08,2019

YSMDP-250 4+2+2 Quartz Double Flat Bevel Edge Polishing Machine,put the material on the conveyor belt, the bottom belt will transport the material into the working area, and the top belt will press the material. At the front of machine, there are 4 st

VIEW 0086-18665475362

0086-18665475362  [email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China