Working Principle Of Water Jet Cutting Machine

The basic technology of

water jet cutting machine is simple and complex.

Simply speaking, the water flow from the pump, through the pipeline, and then from the cutting head, instructions, operation and maintenance is very simple, however, the process is extremely complex materials technology and design.

Under the pressure of 87000 psi to generate high pressure water and to control the water need to master in the practical work of science and technology, and not only the knowledge from the university, if the improper design, high pressure one tiny cracks will cause permanent damage to components.

Thankfully, the water knife manufacturer takes into consideration the complex material technology and the cutting edge design, and the user only needs to understand the basic water knife operation. Basically, there are two types of water knives:

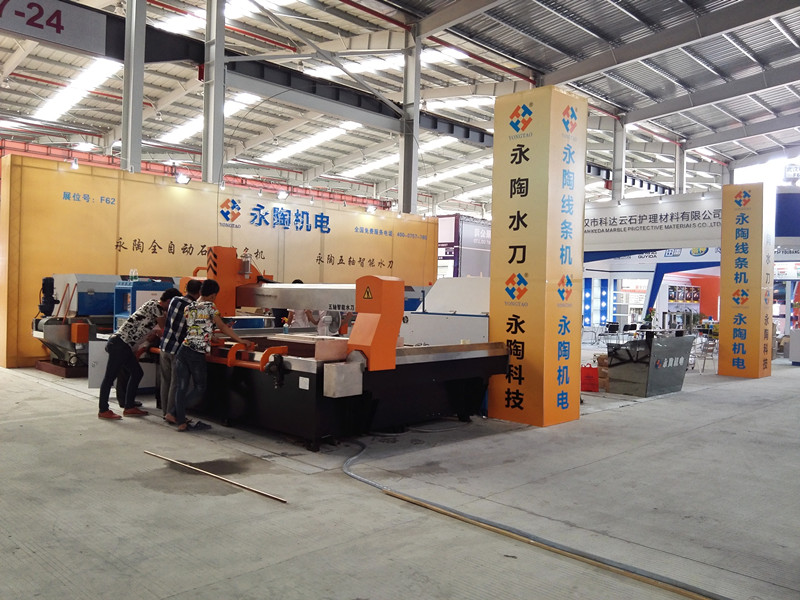

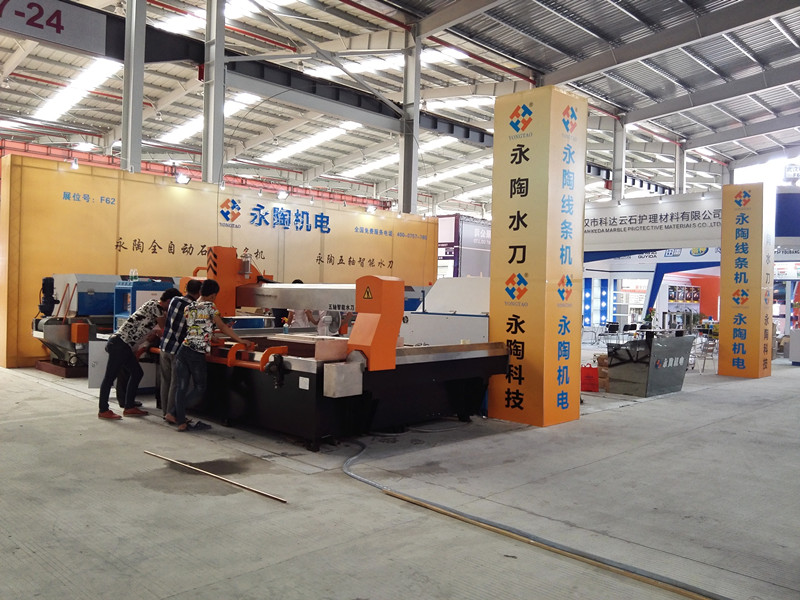

Pure water knife and water jet cutting machine.

Yongtao has a pure water knife and a sanding water knife. Pure water water knife used to cut soft material, and within 2 minutes, this knife can be converted into a monohydrate used for cutting hard material with sand water knife, no matter use which kinds of type, must first to water pressure.

Mobile:0086-18665475362 Web site:

www.chinayongtao.com Email:

[email protected]

Yong tao machinery is a professional production of five-axis CNC water jet cutting machine manufacturers, in China there are a lot of customers in the use, if you want to consult about water jet cutting machine any problems, you can send email or call our telephone number for consultation

0086-18665475362

0086-18665475362  [email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China