Application Of High Pressure Water Jet Cutting Machine

1. Principle of high-pressure water gun:

High pressure cleaning machine, is produced by power plant high-pressure plunger pump high pressure water to flush the object surface, the impact of the water is greater than the dirt and surface adhesion, high pressure will spin out the dirt and water washed away, to clean the surface of a cleaning equipment, high pressure cleaning is the world recognized one of the most scientific, economic and environmental clean way.

1. Application of high-pressure water gun:

(1) all kinds of motor vehicles, engineering vehicles, engineering machinery and agricultural machinery products of cleaning and maintenance, such as car washing, bulldozers, concrete mixer, tractors, etc., is a cleaning cars, motorcycles and small vehicle maintenance unit the ideal cleaning tool.

(2) building external wall, floor, washing the bath, swimming pool, the doors and Windows, floor, toilet, oil, and artificial is especially effective in the corner of the difficulty of cleaning, food factories, food processing machinery and the disinfection of the guesthouse, the restaurant's kitchen cleaning, clean city streets, city crust get rid, animal husbandry health and other fields.

(3) more than 500 atmospheres of ultra-high pressure cleaning machines can be made of concrete, and high-pressure cleaning machines with higher pressure can even cut and chisel the concrete with various marks.

2. High-pressure water jet cutting machine:

1. History of high-pressure water jet cutting machine.

Dr Norman Franz has long been recognized as the father of the water jet cutting machine, he is the study of ultrahigh pressure (UHP) water jet cutting tools of the first, the definition of superhigh pressure is higher than 30000 psi (pounds per inch (2), Dr Franz is a forestry engineer, originally he wanted to find a new way to cut the trunk into wood, his research began in 1950, just when the continuous high pressure is very difficult to achieve, and parts of life is short, high costs and ultimately did not succeed, but Dr Franz proved that high pressure water flow is of great cutting energy, this energy applications far beyond the Dr Franz initial dream.

Dr 1979, Mohamed Hashish in ferro laboratory work, began to study way to increase the water jet cutting energy, so as to cut metal and other hard materials, Dr Hashish add is recognized as the father of the abrasive water jet cutting machine, he invented the method of adding sand material in ordinary water knife, he USES a garnet (a material) on the abrasive paper commonly used as sand material, with this method, water knife (containing sand material) can cut almost any material, in 1980, sand water knife was first used for cutting metal, glass and concrete, in 1983, the world's first commercial sand water knife cutting system, is used for cutting automobile glass, the technology of the first user is the aerospace industry, they found that the water jet cutting machine is used for cutting military aircraft stainless steel, titanium and high strength lightweight composite materials and carbon fiber composite materials ideal tool, from then on, sand water jet cutting machine adopted by many other industries, such as processing, stone, ceramic tile, glass, jet engines, building, nuclear industry, shipyard, etc.

2. The principle of high pressure water jet cutting machine:

Ultra-high pressure water jet cutting is also called the knife and water jet, it is the common water after multistage pressure generated by high energy (380 mpa) water, again through a very fine ruby nozzle (0.1 0.35 mm) Φ, nearly kilometers per second jet cutting, the cutting way called super high pressure water jet cutting.

3. Advantages of high pressure water jet cutting:

(1) the cost savings, but nc forming all sorts of complicated design, water jet cutting can be a complete drilling, cutting, shaping, incision smooth, without slag, no secondary processing, better than the other processing technology, such as flame cutting, plasma processing, laser machining, electric spark machine, milling planer processing, reduce material loss, save energy, thermal deformation or heating in the processing, it is really a multi-purpose high efficient cold cutting processing.

(2) environmental protection, no harmful gas or liquid and dust will be produced during processing.

(3) it can be used for a wide range of materials, such as glass, ceramics, stainless steel, etc., or soft materials such as leather, rubber, paper diapers, etc. It is the only means of complex materials, fragile porcelain materials complex processing. This cold cutting is especially suitable for disposal of scrap bombs or shells.

Mobile:0086-18665475362 Web site:www.chinayongtao.com Email:[email protected]

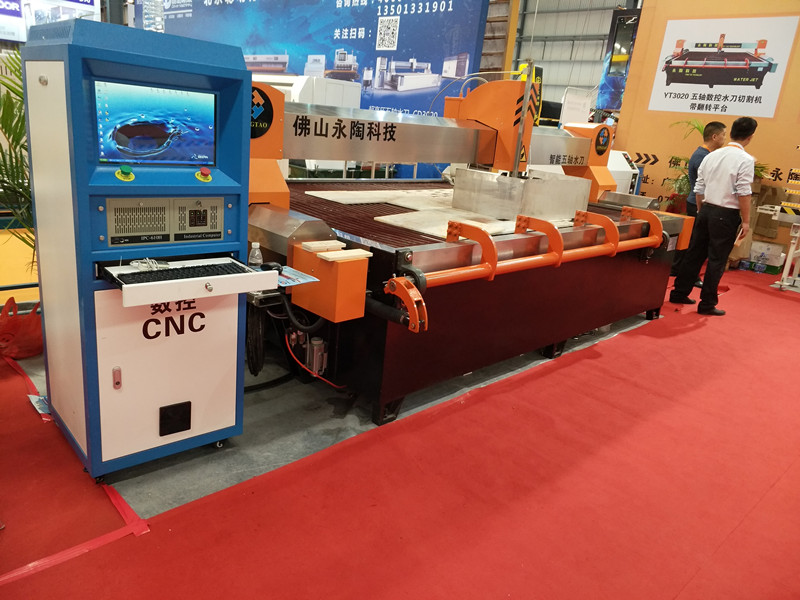

Yong tao machinery is China's famous water jet cutting machine manufacturers, products include three axis five-axis water jet cutting machine, water jet cutting machine and can be customized for clients of various specifications of water jet machine tool, at the same time sales of ceramic cutting machine, stone line, arc polishing machine, stone edge grinding machine and so on all kinds of porcelain stone processing machinery and equipment.

0086-18665475362

0086-18665475362  [email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China