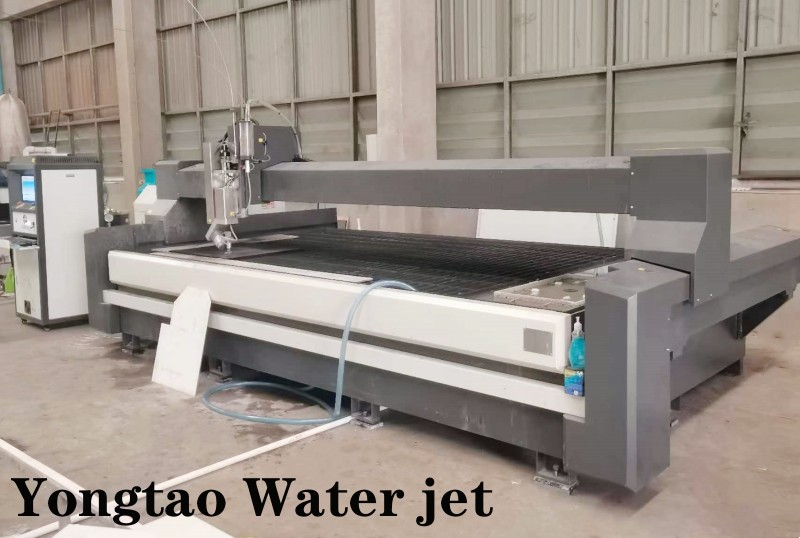

Water jet cutting machine is a new type of cutting equipment, which is widely used in cutting work of various materials. Compared with the traditional cutting method, the water jet cutting machine has no thickness limit and high cutting precision, which can not only reduce material loss, but also ensure the cutting quality. It is widely recognized and occupies an important position in material cutting work.

However, in order to ensure the ideal working performance of the water jet cutting machine, the operator should pay attention to some key points when using it. First of all, the operator must follow the regulations on workpiece placement and fixing to reduce unsatisfactory cutting results or maintenance problems caused by workpiece or material deviation during cutting work. If there is a position problem during the cutting process, other tools should not be used for calibration, but the machine should be shut down in time and re-aligned.

Secondly, it is also very important to monitor the working status of the cutting machine. The water jet cutting machine is a kind of finely-operated mechanical equipment. The operator must monitor the operation of the system at any time, so as to find out the abnormal problems of the equipment in time, and perform corresponding shutdown inspections to prevent the equipment from "working with a disease" and causing unsatisfactory cutting results. Or damage to the system itself and other adverse matters.

Finally, the operator must release the pressure before shutting down the Yongtao water jet cutting machine. Since the water jet cutting machine performs cold cutting under high water pressure, the operation of the equipment contains more high-pressure water. If there is no pressure relief when the machine is shut down or the nozzle is replaced, once it is started, the high-pressure water in the machine will be sprayed out, posing a great hidden danger. Therefore, the pressure should be strictly released before the power failure. If it is an unexpected power failure, the operator should remove the residual high-pressure water as soon as possible, and keep away from the nozzle.

In addition, when using a water jet cutting machine, you need to pay attention to the following points:

1、Regularly check equipment::

Water jet cutting machine is a kind of high-performance equipment, and the normal operation status of its components is very important to the cutting quality of the equipment. Therefore, operators need to regularly check the status of each component of the equipment, including nozzles, high-pressure water pipes, water pumps, pressure gauges, etc., and replace and maintain them in time. In this way, damage and potential safety hazards caused by aging parts during equipment operation can be avoided.

2.、Keep the cutting area tidy:

The cleanliness of the cutting area will affect the cutting effect and service life of the equipment. When using a water jet cutting machine, keep the cutting area clean and tidy to prevent debris or dust from entering the inside of the equipment, which will affect the cutting accuracy and equipment life.

3、Use suitable cutting parameters:

Different materials require different cutting parameters. Therefore, when using a water jet cutting machine, it is necessary to select appropriate cutting parameters according to the actual situation to achieve the best cutting effect. At the same time, it is necessary to perform trial cutting before cutting, and adjust according to the trial cutting results.

To sum up, strictly adhering to the correct operation standard of Yongtao water jet cutting machine is not only the basis to ensure the rapid operation of the equipment, but also the prerequisite for production. The operator must pay attention to placing and fixing the workpiece materials according to the regulations, monitor the working status of the cutting machine in real time, and pay attention to the pressure leakage before closing, so as to achieve the purpose of convenient production. Only in this way can the water jet cutting machine play its best performance and provide better service for the material cutting work.

In short, the correct operating standard is the key to ensure the efficient and stable operation of the water jet cutting machine. Operators need to understand the working principle and operation process of the equipment, operate in strict accordance with the operating instructions, maintain and inspect the equipment regularly, keep the cutting area clean, and select appropriate cutting parameters. Only in this way can the efficient operation of the water jet cutting machine be guaranteed, and the cutting quality and production efficiency can be improved.

0086-18665475362

0086-18665475362  [email protected]

[email protected]

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China

Road 3, Wuzhuang Xiaofengtian Ind. Zone, Luocun Town, Nanhai Dist., Foshan, Guangdong, China